Description of legal entity the legal entity and its main tasks

CEA (French Alternative Energies and Atomic Energy Commission) is a public body established in 1945. CEA is a leader in research, development and innovation, and is active in four main areas: low-carbon energies, defense and security, information technologies and health technologies. In each of these fields, CEA maintains a cross-disciplinary culture of engineers and researchers, building on the synergies between fundamental and technological research. CEA will be involved in the project through its LITEN institute, which is devoted to the development of innovative technologies for the energy transition. CEA LITEN has 950 staff, an annual budget of 130 million euros, and puts in place every year more than 350 research contracts with industrial partners from a wide range of market segments: energy, transport, aerospace, construction, civil engineering, environmental and IT industries, among others. Intellectual Property forms a major part of CEA LITEN activities, with a portfolio of 1,500 international patents. More than 200 articles are published every year in peer reviewed scientific journals.

Tasks and justification in INSTABAT

CEA will lead and coordinate INSTABAT project and the WP5 (Proof of concept multi-sensor platform), WP7 (Dissemination, communication and exploitation) and WP8 (Project Management). Besides, CEA will be involved in all other WPs with different technical divisions and laboratories from LITEN, e.g. the cell assembly laboratory in WP2 and WP5, the post-mortem analysis laboratory for tests to be conducted in WP2, WP3 and WP5 or the modelling laboratory for the development of models and BMS SoX cell indicators in WP4.

CV of the persons

Dr. Olivier Raccurt

CEA Grenoble, 38000 Grenoble Valence, France

ORCID : Olivier Raccurt

SCORPUS : Olivier Raccurt

Dr. Sylvie Genies

CEA Grenoble, 38000 Grenoble Valence, France

ORCID : Silvie Genies

Dr. Sónia Sousa Nobre

CEA Grenoble, 38000 Grenoble Valence, France

Dr. Yvan Reynier

CEA Grenoble, 38000 Grenoble Valence, France

Dr. Mathias Gérard

CEA Grenoble, 38000 Grenoble Valence, France

Dr. Vincent Heiries

CEA Grenoble, 38000 Grenoble Valence, France

Dr. Elise Villemin

CEA Grenoble, 38000 Grenoble Valence, France

ORCID : Elise Villemin

SCOPUS : Elise Villemin

LinkedIn : Elise Villemin

Research Gate : Elise Villemin

LIST of relevant publications

- M. Chandesris, et al., “Thermodynamics and Related Kinetics of Staging in Intercalation Compounds”, The Journal of Physical Chemistry C 2019 123 (38), 23711-23720, 2019

- N. Gauthier, et al., “Efficient sensitization of Ln3+-doped NaYF4 nanocrystals with organic ligands”, Journal of Nanoparticle Research,Vol. 15, p.1723, 2013

- N. Wartenberg, et al., “Multicolour optical coding from a series of luminescent lanthanide complexes”, CHEMISTRY - A EUROPEAN JOURNAL, Volume 19, Issue 10, pages 3477–3482, March 4, 2013

- P. Kuntz, et al., “Evolution of the safety behavior of Li-ion battery after aging”, EVS32 Symposium, Lyon, France, May 19-22, 2019

- P.H. Michel and V. Heiries, “An Adaptive Sigma Point Kalman Filter Hybridized by Support Vector Machine Algorithm for Battery SoC and SoH Estimation”, 2015 IEEE 81st Vehicular Technology Conference, 2015

List of relevant previous projects

- H2020 project BATTERY 2030+ (BATTERY 2030+: At the heart of a connected green society), where CEA is project deputy coordinator

- H2020 project TEESMAT “Open innovation test bed for electro-chemical energy storage material)” where CEA is the project coordinator

- H2020 project EVERLASTING “Electric Vehicle Enhanced Range, Lifetime And Safety Through INGenious battery management”, where CEA had the role of WP leader

- H2020 project OBELICS “Optimization of scalaBle rEaltime modeLs and functIonal testing for e-drive ConceptS”

- Horizon 2020 project NENUFAR “Next gEneration of eNergy storagE solUtions For more electricAl aiRcrafts”, where CEA is project coordinator

Description of any significant infrastructure

For INSTABAT project, CEA in particular use the following platforms

The BATTERY platform (3,000 sq. m of facilities, including 1,000 sq. m of dry rooms) is a technology infrastructure gathering all the tools required to develop and produce small series of Li-ion batteries at the pilot scale. R&D at the platform starts with identifying and synthesising materials to optimise battery performance and encompasses manufacturing the various components (such as battery electrodes and electrolytes), assembling the battery packs, and integrating them into complete systems. Battery safety is assessed via a range of tests that include total destruction of the battery. The platform has around 20 pieces of heavy equipment, including coating and filling machines and a test assembly line. The platform work focuses on lithium-ion battery cells and packs of all sizes, from tiny hearing-aid batteries weighing in at just a few grams to 300-kg electric-bus batteries. With a strong commitment to industrial R&D partnerships, the platform collaborates with several leading companies across the value chain.

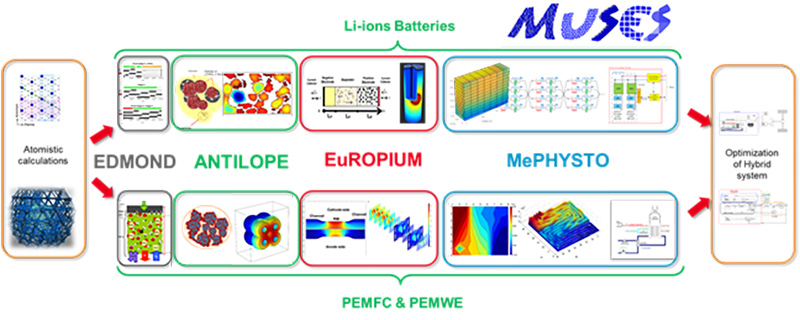

The modelling platform called MUSES, which is a multi-scale and multi-physics modelling and simulation platform dedicated to the study of PEMFC, PEMWE and Li-ions Batteries, focuses on performance, safety and durability aspects. The different models of the platform, from material to system, are developed with a common material and physical database and a multi-scale methodology. The versioning and test cases for no regression of the platform allow model co-developing. In particular for the Li-ions battery, the atomistic and meso-scale (ANTILOPE environment) are focused on (1) the upscaling of ab-initio properties to the thermodynamic and kinetic of the electro-chemical reactions; (2) simulating performance, durability and mechanical swelling at the agglomerate scale based on real or virtual images. The microscale (EuROPIUM environment based on PDE equations solved with finite element methods, by Comsol multiphysics solver) focuses on linking the performance and durability at the: (1) electrode scale, by coupling electro-chemical with complex transport phenomena in the different phases with degradation mechanisms, in order to understand and optimise electrode design; (2) cell scale to optimise cell design and to understand and predict thermal runaway; (3) module and pack scale to validate the thermal conception and predict the thermal runaway propagation. The cell and system level (MePHYSTO environment based on ODE equations solved with a lump model approach and bond-graph construction, by Matlab/Simulink solver) is dedicated to lifetime prediction and optimisation of battery management in the system and battery pack optimisation sizing.